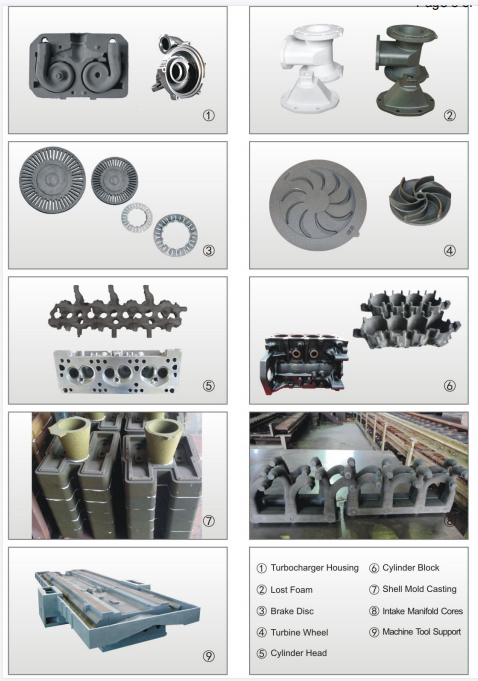

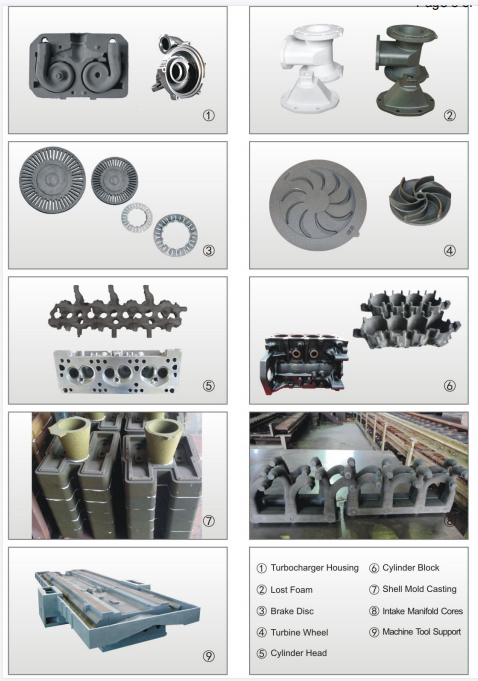

High Reclamation Yield Spherical Ceramic Sand For Mining Machine

Spare Parts

1. Spherical ceramic sand for foundry Mining Machine Spare Parts

In order to reduce waste emissions and health hazards to people in

classic foundry process, as well as to improve foundry efficiency.

Due to ceramic sand outstanding properties, ceramic sand has been

widely used in most types of foundry process as an upgrade

substitution of silica sand and special foundry sands.

2.CERAMIC SAND characteristic ;Mining Machine Spare Parts

Anti - Burn on

High Reclamation Yield

Thermal Expansion Control

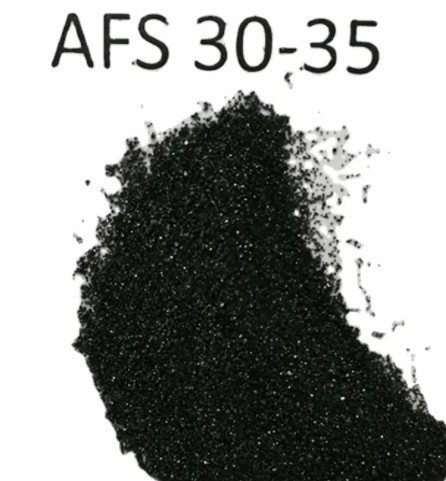

Wide Choice of Particle Size

Reduced Waste and Health Hazard

Good Flowability and Heat Conductivity

Low Resin Consumption and Gas Defects

| Main Chemical Component | Al.O:70~85%,Fe,O,≤5%,TiO.:3~4%,SiO::12~25% |

| Shape | Good spherical |

| Angularity Facto | ≤1.1 |

| Particle Size | 0.053mm~2.50mm |

| Bulk Density | 1.95~2.051(g/cm³) |

| Thermal Expansion | 0.13%(10 minutes at 1000℃) |

3.Why Ceramic Sand Mining Machine Spare Parts

1) Prevention of sand expansion defects, especially finning/veining

2) Elimination of gas-forming additives

3) Prevention of reactions between metal and moulding sand

4. Prevention of metal penetration

5) Reduction of core weight

6) Improved flowability of moulding sand

7) Influence on the formation of microstructure

8) Pouring of thin-walled castings

4. Pimary Customers Abroad (Mining Machine Spare Parts)

| Foundry process | Type of metals | Castings weight | Sand spec. | Technical purpose | Country |

| Phenolic urethane no-bake | Low alloy steel carbon steel | 0.5~4 tons | AFS 85 | Replacing zircon | America | |

Ester cured phenolic no-bake | Stainless steel, carbon steel | 100 tons | AFS 85 | Replacing zircon | Japan | |

| Alpha-set molding line | Carbon steel, low alloy steel | 0.5~15 tons | AFS 55~70 | Replacing zircon/silica sand | Korea | |

| Shell | Ductile iron | 10~40 kgs | AFS 85 | Replacing zircon/silica sand | America | |

| Cold box/shell/hot box | Grey cast iron | 20~300 kgs | AFS 50~95 | Replacing silica sand | Germany | |

| Alpha-set molding line | Carbon steel,low alloy steel | 50~400 kgs | AFS 65 | Replacing zircon/silica sand | Japan | |

| Cold box/shell/hot box | Grey cast iron | 10~200 kgs | AFS50~65 | Replacing silica sand | ltaly | |

Furan no-bake molding/shell/hot box(RCS) | Grey cast iron | 20~400 kgs | AFS 55~115 | Replacing silica sand |

UK | |

Furan no-bake molding/core making | Grey cast iron | 100~500 kgs | AFS 50 | Replacing silica sand | South Africa | |

Furan no-bake molding/core making | Grey cast jron/Ductile jron | 50~400 kgs | AFS 40 | Beplacing silica sand | Austria | |

| Lost foam(EPC) | Grey cast iron/Ductile iron | 30~3000 kgs | AFS 15~25 | Replacing silica sand | Korea | |

| Furan no-bake molding | Grey cast iron (Machine tool parts) | 0. 5~30 tons | AFS 25~40 | Replacing silica sand | Thailand | |